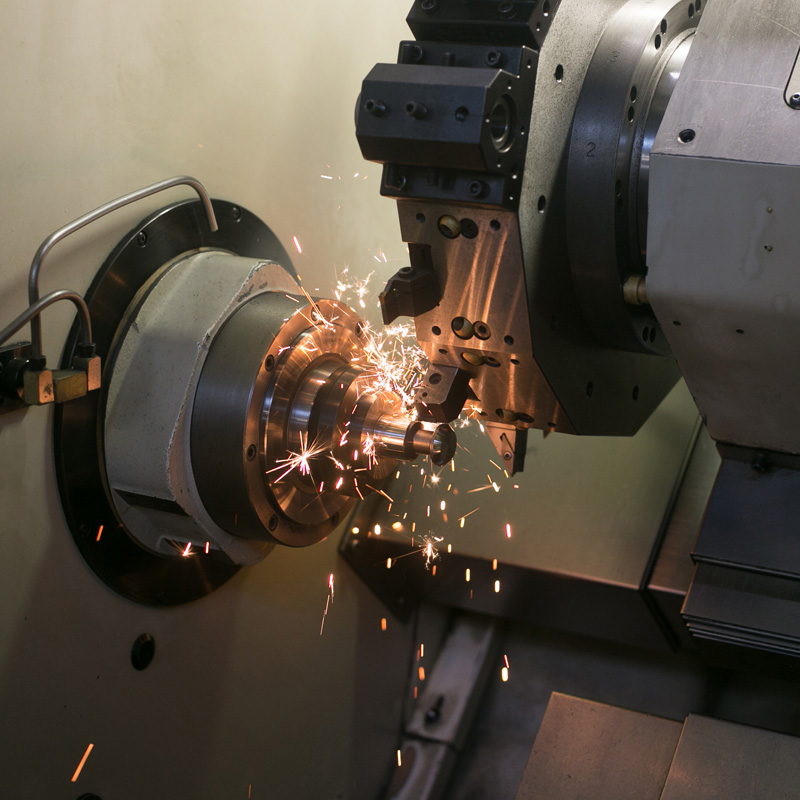

For 44 years, Tessari has been operating to the highest standards in the field of traditional and CNC precision mechanical grinding. Over time it has developed vast experience in the production of mechanical components, strongly believing in the culture of absolute precision and the continuous search for mechanical perfection.

Quality and results for everyone

Extreme specialisation in precision grinding, with guaranteed results and conformity to all tolerance levels required by the customer

The ideal partner for machining mechanical components with the smallest tolerances. A reliable partner in fully meeting each customer's specifications.

Guaranteed quality in all areas of the company, thanks to the UNI EN ISO 9001:2015 certified system that ensures absolute reliability of production at industrial level.

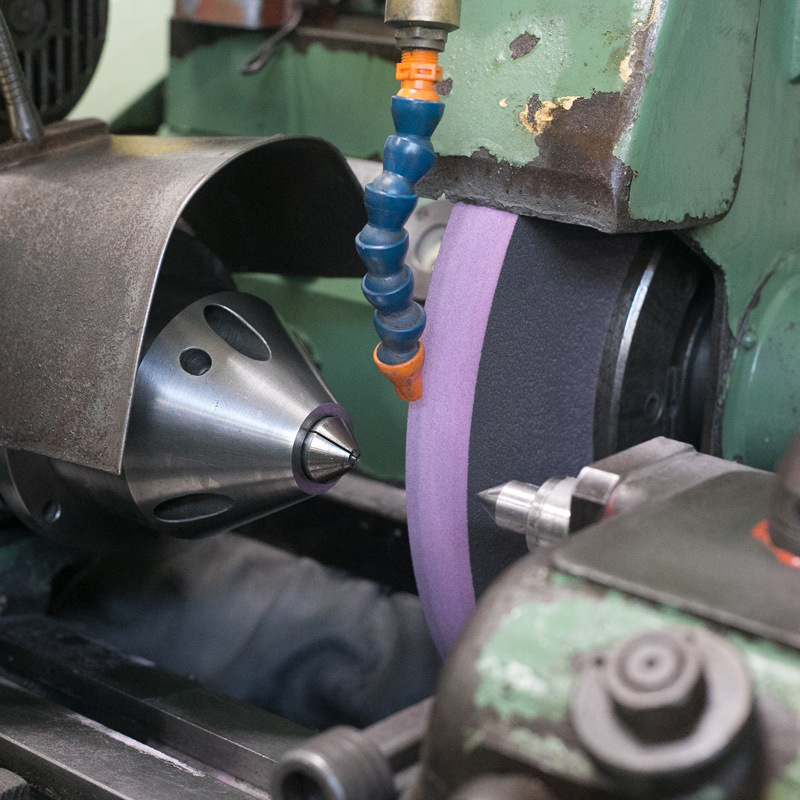

Precision grinding specialising in small and very small parts

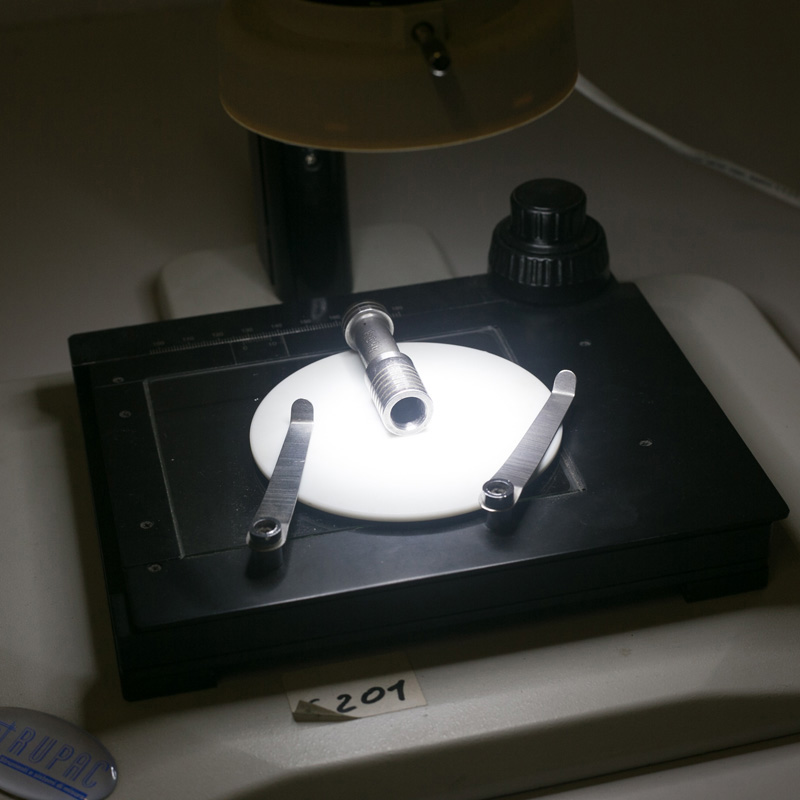

Tessari, a grinding specialist, especially for small and very small parts. Thanks to its long experience, it is able to take care of all machining stages and meet everyone's needs: after receiving the drawing and semi-finished products (turned and heat-treated parts), it verifies the feasibility of the required machining method to proceed with grinding, and then continues with quality control, packaging and delivery.

Products machined by Tessari have diameter tolerances down to hundredths or, more often, thousandths of a millimetre. The high quality standards of the machinery and personnel allow for extraordinary roughness results down to 0.2 Ra.

Tessari is always pushing the envelope, in technology as well as in in-house knowledge, to always achieve competitive prices and on-time delivery. This is demonstrated by the continuous updating of its machine inventory, such as the recent purchase of an additional hard turning machine, which increases the precision of machined parts and reduces the throughput time

Mechanical and hydraulic components production service

Our vast machine inventory

- TACCHELLA Centre Grinder (max. length 500 mm, max. diameter 60 mm, min. diameter 2 mm)

- MIKRA CNC LIZZINS centre grinder (max. length 550 mm, max. diameter 50 mm)

- 2 CNC lathes for hard turning

- SCHAUDT Traditional copy grinder for grinding small hydraulic components (max. diameter 30 mm, max. length 200 mm)

- FAVRETTO Tangential grinder (working table 350mmx700mm)

- GHIRINGHELLI Centreless throughfeed grinder (min. diameter 5 mm, max. diameter 50 mm)

- GHIRINGHELLI Centreless plunge cut grinder (min. diameter 1.5mm, max. diameter 40mm)

- SUNNEN Conventional lapping machine for small diameters up to 31.75 mm

- 3 Vibratory rock TUMBLERS for ground workpieces

- 2 TORNOS Swiss-type lathes (max diameter 26 mm)

- 2 MORI SEIKI Lathes, bar transit 40 mm

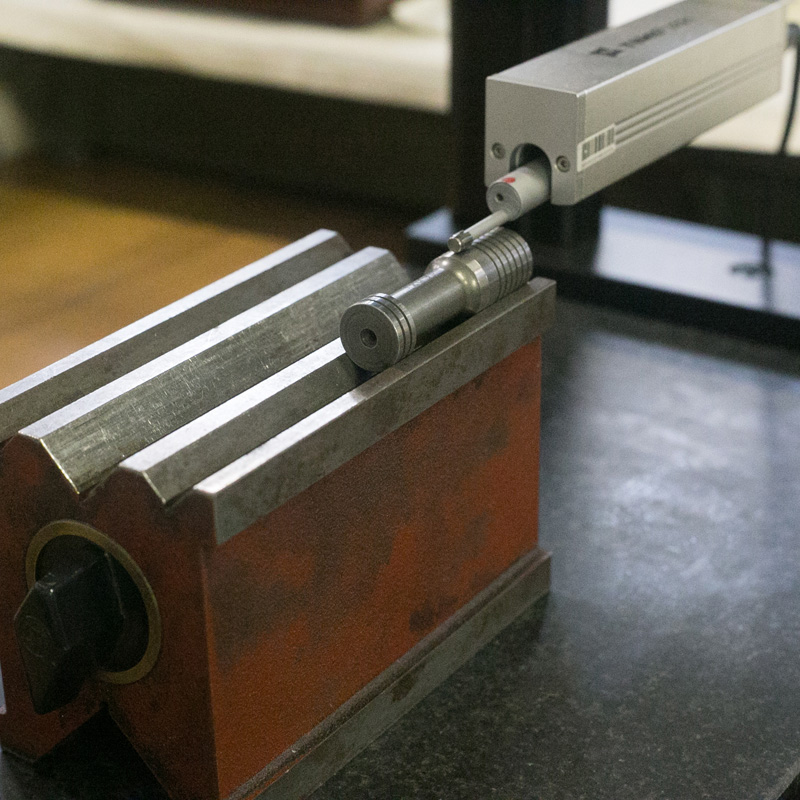

- Z-MIKE Laser Micrometer

- RUPAC Roughness tester

- MITUTOYO Concentricity gauges

- BAKER/MITUTOYO Bore meters

- STARRETT Optical comparator

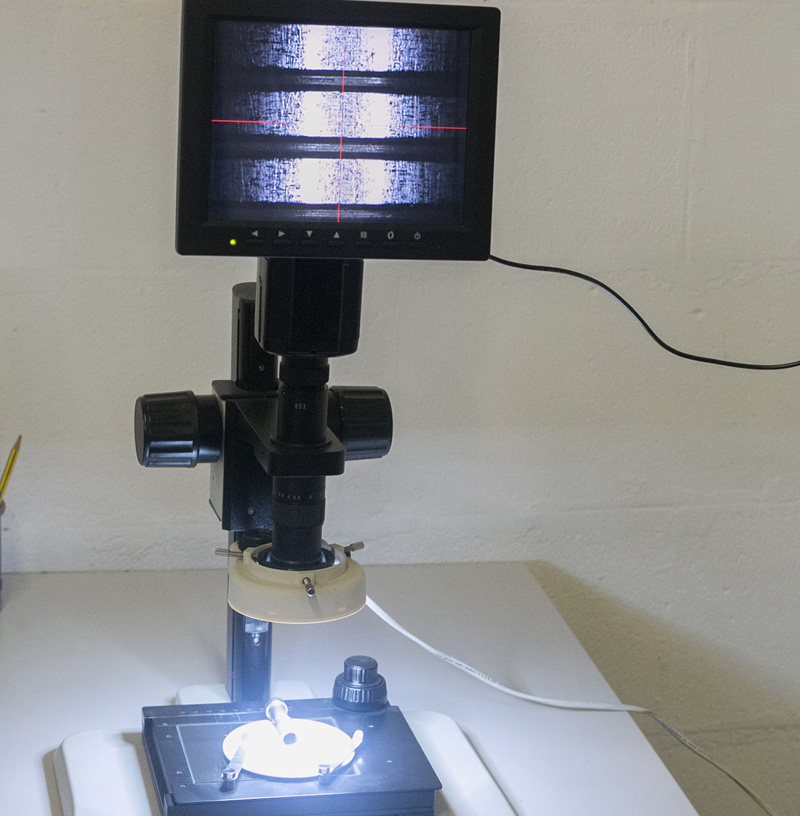

- RUPAC Video microscope

- MITUTOYO Roundness tester

- MITUTOYO Micrometers with hundredths and thousandths measurements

- MAHR Roundness teste

Materials machined

- 16NiCr4

- 11SMnPb37

- 16NiCrS4

- 1.4404

- 9SMnPb36

- 1000Cr6

- Sp52-3

1.4305

(case hardening steels, stainless steels)

Production quantities:

- 10 pieces

- 100 pieces

- 500 pieces

- 1000 pieces

- 10.000 pieces